3D Printing in Space: A New Frontier for Repair and Manufacturing

With talks about NASA’s astronauts potentially not making their way home until March to Elon Musk’s vision of colonizing Mars, space has been at the forefront of everyone’s minds lately.

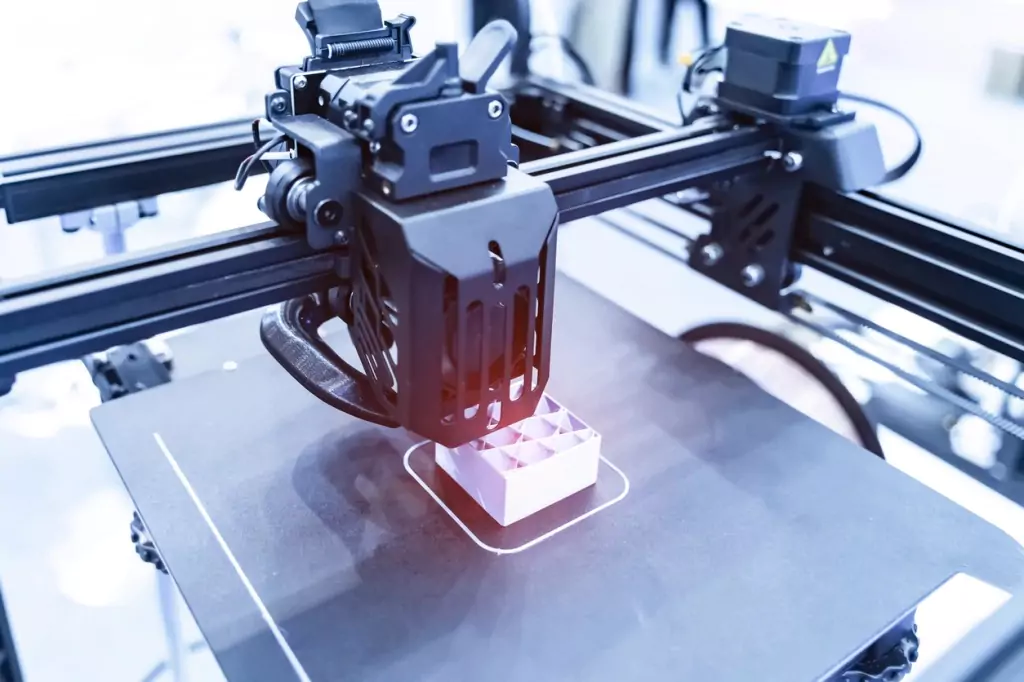

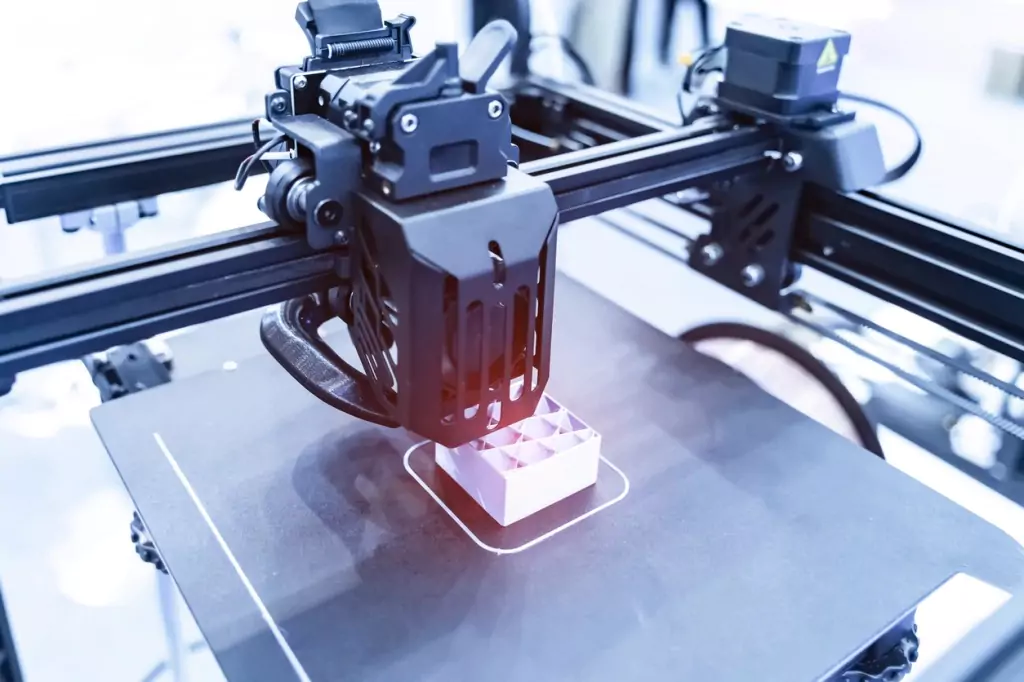

While there are new advancements in space technology every day, a prominent topic in the industry is how 3D printing, also known as additive manufacturing, is revolutionizing space repair and manufacturing. From the creation of tools to replacement parts, 3D printing has opened a new world and is ready to take the universe by storm.

While we can date the 3D printer back to the early 1980s, 2008 was the year that the technology became more accessible for commercial use. By the late 2010s, there were over 170 3D printer manufacturers worldwide, and every day since then, people and corporations have taken digital files and added layers of material to create objects.

There are many benefits of 3D printing in space. Instead of launching a large inventory of spare parts, astronauts can print them on demand, saving storage, time, and weight on the spacecraft while also being more feasible than transporting these parts from Earth. Because the printer is creating a replica of a file, little waste is generated, so there are minimal concerns about waste disposal in space. Astronauts can also create custom tools for specific repair tasks, even if those tools weren’t originally part of the mission’s equipment.

While there are positives to additive manufacturing use, there are some challenges. According to space.com, “many methods rely on gravity to position materials during the printing process.” The molten metal material can often become skewed in development or be placed in incorrect areas due to shifts and a “lack of gravitational forces.” Thankfully, scientists have worked relentlessly to tackle these challenges and adjust specific printers to microgravity environments.

In 2020, NASA launched the Perseverance Rover to Mars with eleven 3D metal parts and tools. The Delft University of Technology used Zebro robots to 3D-print underground structures on Mars, assessing their suitability for colonization. Companies are developing rocket engines quicker than ever by creating and printing parts on Earth. Everywhere you turn in this industry, 3D printing is making things easier, more efficient, and more feasible.

While 3D printing’s progress is significant, it won’t eliminate traditional manufacturing of tools and parts. You can rely on us when you need repairs on crucial space equipment, such as HMIs, VFDs, and more! Call us today.