Precision Servo Motor Repair Services

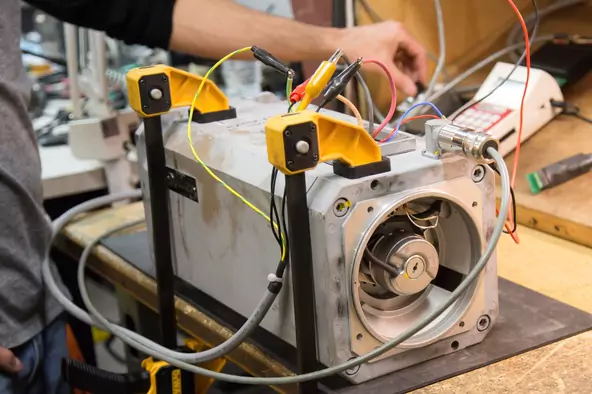

At Industrial Repair Service, our Servo Motor Shop is built to keep your automation running at peak precision. Outfitted with advanced diagnostic systems and specialized equipment, this facility is designed to handle a wide range of servo motor challenges, from routine inspection to complete overhauls, with OEM-level accuracy.

Brands We Service

Our Repair Capabilities

Our technicians have the experience to diagnose and repair a wide range of servo motor issues. We don't just fix the problem; we remanufacture the motor to its original factory specifications.

- Complete Disassembly & Cleaning: Every motor is fully disassembled, cleaned, and inspected to identify all points of failure.

- Precision Component Repair: We repair or replace worn components, including bearings, seals, encoders, resolvers, and connectors.

- Advanced Testing: After reassembly, each motor is run test performed to ensure it performs exactly as it should.

Diagnosing Common Servo Motor Faults

We resolve all common mechanical and electrical servo motor issues to restore peak performance.

Bearing Failure

We replace worn or seized bearings—the most common point of failure—to eliminate noise, vibration, and overheating.

Encoder/Resolver Faults

Our lab can repair and align all types of feedback devices to resolve positioning errors and runaway conditions.

Winding Shorts

Experienced technicians test for shorts between windings and perform precision repairs or replacements to restore proper motor performance to OEM standards.

Brake Malfunction

We repair or replace failing brakes to ensure your motor holds its position correctly and operates safely.

A Complete Remanufacturing Process

Our service is more than just a repair. We perform a complete remanufacturing of every servo motor, restoring it to a like-new condition to ensure it provides years of reliable service in your facility.

- Precision Alignment: All feedback devices are precisely aligned to the motor shaft using OEM software and hardware for perfect communication.

Our Servo Motor Repair Process

Initial Testing & Disassembly

We run an initial test to check the feedback and brake. The motor is then completely disassembled and all parts are cleaned.

Remanufacturing & Reassembly

All necessary repairs are performed, windings are checked, and worn components like bearings and seals are replaced.

Run Testing & Alignment

The motor is run for an extended period under load, and the feedback device is precisely aligned before shipment.

Advanced Technical Resources

- Multiple test stands for full encoder and resolver alignment

- Diagnostic units from Heidenhain and SICK

- Back-EMF test stand for verifying magnet strength

- Baker Winding Analyzer for comprehensive testing

- Wide array of drives for closed-loop run testing

- In-house 3D design and printing for obsolete parts

- Full suite of machining and cleaning equipment

Model-Specific Testing Platforms

- Mitchell System – Servo motor diagnostic and alignment

- Yaskawa SGDV – Servo motor series testing

- Baldor Vector Drive – Spindle motor validation

- Indramat RAC Series – Spindle drive testing

- Siemens 6SC Series – Spindle drive testing

Core Service Capabilities

- AC and DC servo motors

- Spindle motors

- Pitch motors for wind applications

- Encoder-based systems requiring precise feedback

Our Competitive Advantage

- Purpose-Built Facility: Dedicated exclusively to servo motor repair and testing.

- Extensive Testing Capabilities: From encoders to windings and magnets.

- Custom Fabrication: In-house 3D printing to solve obsolete part challenges.

- Comprehensive Tooling: Unmatched versatility from diagnostics to finishing.

- Reliability Backed by Warranty: Every repair is fully tested and covered.

Select Your Brands for Repair

Click on the servo motor brands you need serviced to add them to your list.

Get a Free Quote for Your Servo Motor Repair

Our flat-rate quotes have no hidden fees. Ship us your motor or arrange a free pickup in our service area to get started.

Request Your Free QuoteRequest a Repair Quote

Fill out the form below, and we'll get back to you shortly.